Our patended Wave Cryogenic and

Refrigeration Technology creates a gas wave system using pressure drop of

process vapor stream. By controling such a gas wave system, several different

engineering goals. For instance, the compressible waves created in the aforesaid

gas wave system can generate a higher temperature effect which makes system

energy easily removed. Meanwhile, an expansion wave system will reduce system

temperature to make refrigeration more effective. The unique feature of this

technology, is that such a system can be implemented without using any moving

part in our device. This feature will significantly increase operation

reliability, reduce the operation and maintenance costs, and enhance the

efficiency of applied industrial systems and processes.

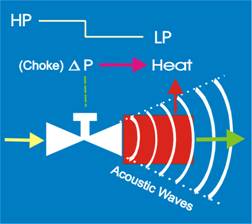

Chokes

and J-T valves control pressure drop and waste all energy by throttling

dissipation due to the simple structure with no moving parts, and expanders can

extract pressure energy by a complex moving structure that results in lower reliability and limit on operating conditions. In contrast to conventional

chokes and expanders currently used in oil & gas industries, the PWECT

products integrate the merits in both devices (pressure controlling

and energy extraction with no moving parts), handling pressure reduction

energy efficient while retaining the simplicity and reliability of its

structure. The operation of PWECT products is illustrated in the

left figure. When a pressurized stream flows through a PWECT

device, pressure drop is used to drive periodic gaseous wave systems rather than

a mechanical part or being throttled through a constrained orifice. The cooling

and heating effects are produced by periodic wave systems (compressible and

rarefaction waves), and heat is removed from pressure drop in order to increase

cooling efficiency even being in the conditions of varying flow states.

Applying pressure energy to

generate refrigeration is a fundamental thermodynamic cycle which have been used

in a broad field of both commercial and residential industries. In summary, WCRT

technology has a broad base of industrial applications and thus variant

marketing potentials.

The potential applications of the CWAT's new technology

covers broad industrial fields in both common and high-technical industries. In

the common industrial area, the potential applications of CWAT's products can be

applied to a variety of processes and systems in common industries as well. In

those where pressure drop is available and cooling or heating effects are

needed, companies and plants, such as oil refinery plants, systems of off-shore

oil and gas extraction, liquefied natural gas (LNG) processes, industrial gases

liquefaction systems can benefit. The marketing goal of CWAT is to provide

quality products to improve the existing systems and production processes.